Most remember the days as a kid when it was there turn for show and tell at school…you went home and spent hours trying to decide what to bring, to show off and talk about, in hopes it made you just a little bit cooler than the other kids in class. Well GM (General Motors), became a bit cooler the other day, when they showed up with a brand-new Cadillac XT4 SUV, part of the E2UL program. The Colonial family, Colonial Mold was awarded eight (8) tools to build as part of this program and Colonial Plastics currently molds and ships fifteen (15) parts for final console assemblies that GM orders on this platform.

“It’s not just about marketing the car or giving people the opportunity to take a break, it’s about helping our partners to boost morale and give our customers and their employees, who make the parts every day, a chance to see what they’ve created and where in the car, the parts actually go and how they function, ask questions…” says Rich Uhlman, part of the Global Supplier Quality & Development Team for interiors at GM

We have to say, it did just that and we could not agree more with Rich’s comments. However, we did notice that it also did something else in the days to follow, and that is it helped to bring more awareness to the quality level, the parts need to be. Because of the interaction with the car and actually getting to see the parts they made in the car, more of our employees now realize that they are making parts for a Cadillac, a well-respected and high-end brand in the automotive industry. Operators appeared to be paying more attention to the parts coming off the press and we even heard one employees talking with a supervisors and taking the extra minute to ask if the part they had was ok to box before the quality team certified the parts, that they didn’t want to be responsible for shipping a bad part to be put on the car they got to see the other day. It was rewarding to witness.

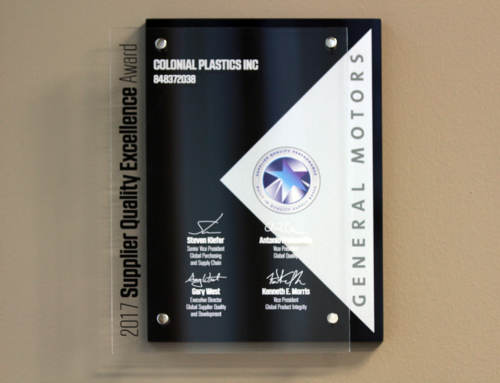

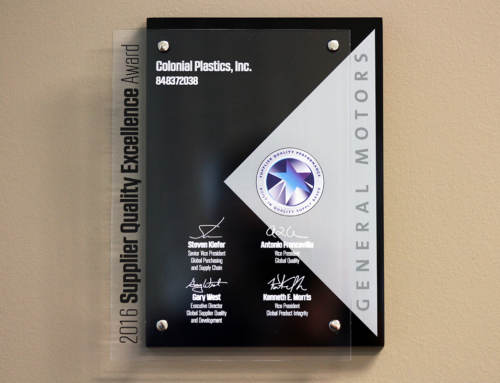

If you didn’t know, Colonial Plastics Inc. has earned GM’s highest quality honor, the Supplier Quality Excellence Award, four (4) years running, so we take quality very seriously and we are always looking for newer and more creative ways to assure the quality of parts we make are the best we can mold for our customers. The time and opportunity GM took to bring an XT4 out to our facility, so our people get to see what they make in final format and be a part of something bigger, was truly inspiring and another step-in advancement and continuous improvement in our eyes.

We are truly blessed, and we thank you again GM for this opportunity. Every day, people are asking when and who is going to bring the next car out.