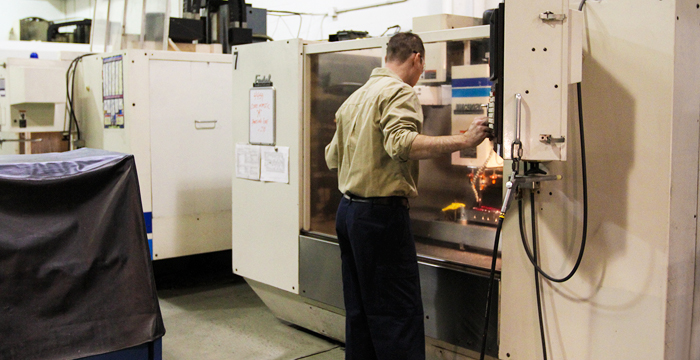

Proudly Manufacturing In The USA Since 1985

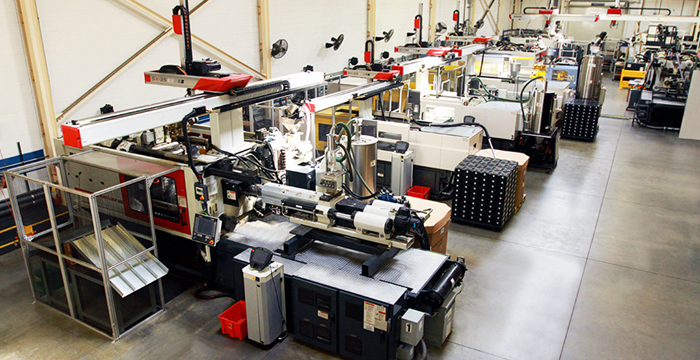

Explore One Of Our Divisions Below & See How We Can Help Add Value To Your Process

Certificates And Awards

Click Below To Read More About This Years Award

Click Below To Read More About This Years Award

Click Below To Read More About This Years Award

Click Below To Read More About This Years Award

Women Owned

Proudly operating, Michigan based, certified minority-owned business...CERTIFICATE #2005121118

Quality Control

Always achieving the highest level of quality to protect our customers...IATF 16949 CERTIFIED

Innovative Awards

Always ahead of the competition with new innovations and technology...MOST INNOVATIVE USE OF PLASTICS

List Of Services

Who Is Colonial Group, Inc.

• Believing that meeting the highest standards is not a job, but a tradition

• Continually improving the effectiveness of our quality management system.

Our certifications for the QMS standards have been in place as long as QS/TS and ISO existence. Our dedication to quality continues, recently updating to IATF-16949:2016 and acheiving GM’s highest quality of excellence award, 4 years running!

Our Comprehensive Quality Program is practiced through all stages of the manufacturing process including:

• Feasibility Assessments

• Capacity Planning

• Control Planning

• Consistent setup and operation of processes to production plans

• Testing and training plans designed for each product compliance to applicable standards

• Inspections of all products by Quality Assurance Personnel

• Final Inspection prior to shipment

• Regular feedback on performance, issues, and improvement plans is gathered and acted upon to continuously improve our operations and customer experience

• OEM Compliant Procurement’s Practices

• Sustainability Concerned

• Measured Quality Objectives

• 3 yearly Improvement Plans that add value to our products and services

• Our Employee Involvement Program

• Internal and External Audits designed to include all employees in the application of our quality

The disciplines outlined have proven to be the cornerstones of Colonial Groups rapid growth and success in today’s demanding global Markets.

- ABC Group (Colonial Plastics, Inc. – Production) – CO1605

- Alpine (Colonial Plastics, Inc. – Production) – 60004515

- BorgWarner Thermo Sys. (Col. Plastics, Inc. – Production) – 301092

- Case New Holland (Colonial Plastics, Inc. – Production) – JF171

- Chrysler (Colonial Mold, Inc. – Tooling) – 97889

- Chrysler (Colonial Plastics, Inc. – Production) – 13476

- Chrysler Daimler (Colonial Plastics, Inc. – Production) – ET29

- Donaldson (Colonial Plastics, Inc. – Production) – 37972

- Flex N Gate (Colonial Mold, Inc. – Tooling) – COL100

- Ford (Colonial Mold, Inc. – Tooling) – CDFLA

- Ford (Colonial Plastics, Inc. – Production) – AUNTA

- Formed Fiber (Colonial Plastics, Inc. – Production) – 104822

- Freightliner (Colonial Plastics, Inc. – Production) – ET29

- GE (Colonial Plastics, Inc. – Production) – CM160A

- GM (Colonial Mold, Inc. – Tooling) – Duns# – 147195275

- GM (Colonial Plastics, Inc. – Production) – Duns# – 848372038

- GM (Colonial Plastics, Inc. – Production) – SPO Source#: 05163

- GM Components Holding (Colonial Mold, Inc. – Tooling) – 1016284

- GM Z Code (Colonial Mold, Inc. – Tooling) – BJP5

- GM Z Code (Colonial Plastics, Inc. – Production) – BM3T

- Goodrich Cabin Sys. (Colonial Plastics, Inc. – Production) – 00313

- Henkel (Colonial Mold, Inc. – Tooling) – 260591

- Henkel (Colonial Plastics, Inc. – Production) – 374658

- Hutchinson (Colonial Plastics, Inc. – Production) – 86-0412

- Johnson Control (Colonial Mold, Inc. – Tooling) – 50020680

- Key Safety (Colonial Plastics, Inc. – Production) – MFG4447

- Magna (Colonial Plastics, Inc. – Production) – 05224

- Nexteer (Colonial Mold, Inc. – Tooling) – Vend # 20005123

- Nissan (Colonial Plastics, Inc. – Production) – C750

- Robert Bosch (Colonial Plastics, Inc. – Production) – 97201807

- S Group (Colonial Plastics, Inc. – Production) – 50000146

- TRW (Colonial Plastics, Inc. – Production) – 236981

- Unicar Plastics (Colonial Plastics, Inc. – Production) – 10851

- Volkswagen (Colonial Plastics, Inc. – Production) – 848372038

- Wixom Technologies (Colonial Plastics, Inc. – Production) – COLO

Terms and Conditions Coming Soon